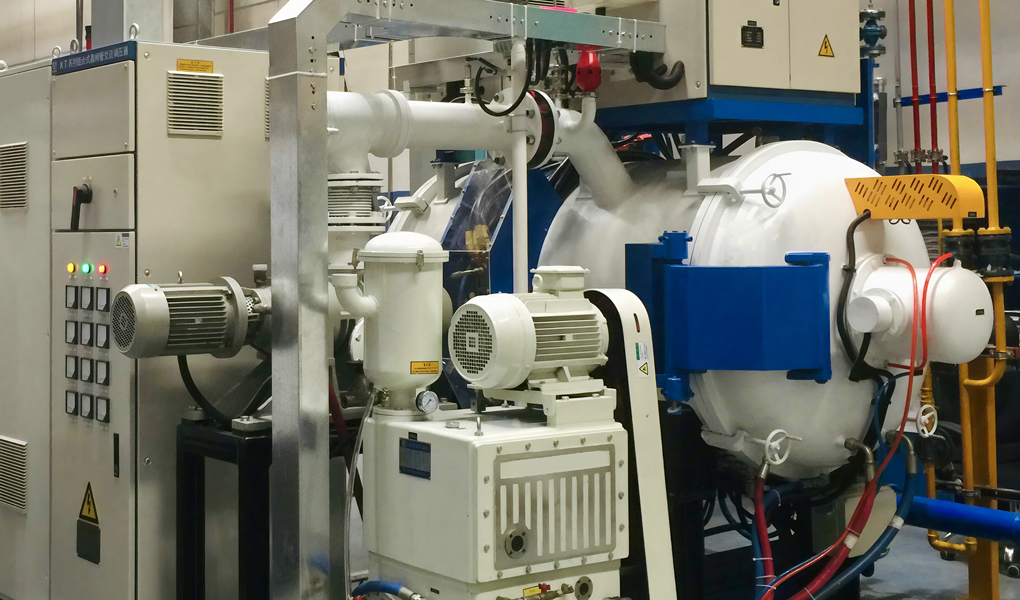

Vacuum Sintering Furnace

Vacuum Sintering Furnace

Shintek Vacuum Sintering Furnace is widely used for varieties of material industries, including powder metallurgy sintering furnace, MIM sintering furnace, Dewaxing furnace, hot-pressing furnace and so on, can support material R&D and production of hard metal, refractory metal, magnetic material, injection stainless steel, photoelectric material, rare earth, synthetic diamond, ceramic and related material industries.

Shintek can provide:

- Furnace parts or semi-finished materials (Single part is available for sale.)

- Total Vacuum Furnace solution as a Turn-key project.

- Furnace repairing service

Features of Shintek Vacuum Sintering Furnace:

- Patented hotzone design enable a lower power consumption and higher efficiency;

- High vacuum level, enable it can be used for a wide of industries.

- Several heating elements for choosing, customized for your specific application: Graphite, SS, Ni-Cr, Mo, MoLa, TZM, Tungsten…

- Reasonable hotzone design enable a high temperature uniformity;

- Friendly control system.

Typical Shintek Vacuum Sintering Furnace:

| Model | STVF-S-2/65 | STVF-S-2/80 | STVF-S-2/120 | STVF-S-2/150 | STVF-S-2/200 | STVF-S-2/550 |

| Working zone | 420*300*300 | 600*400*400 | 750*500*500 | 900*600*600 | 1200*800*800 | 1600*1200*1200 |

| Load (KG) | 100 | 200 | 300 | 500 | 1000 | 2000 |

| Power | 65KW | 80KW | 120KW | 150KW | 200KW | 550KW |

| Max. temperature: 1800℃ (metal resistance); 2200℃ (Graphite) | ||||||

| Temperature uniformity: +/-5℃ | ||||||

| Ultimate vacuum level (Cold): 8*10-4 Pa (Metal resistance); 5*10-3 Pa (Graphite); | ||||||

| Leakage rate ≤0.5 Pa/h | ||||||

Note: The customization of Vacuum Sintering Furnace for your specific project is available.

Need semi-finished raw material for making furnace?

or Need furnace parts?

or Need a total solution of Vacuum Sintering Furnace?

Please feel free to contact us. Let us know more about your requirements and working condition. You will get a professional proposal after then.